|

ALD (Atomic Layer Deposition) technology was introduced to the light-emitting devices to significantly increase their luminous efficiency in the Institute of Microelectronics of Chinese Academy of Sciences (IMECAS) in Late-March 2013.

In the 1980s, ALD was first put forward by the Finland scientist and applied in the deposition of Al2O3 insulation film in the flat panel displays. In 2007, ALD technology was introduced to 45 nm node and integrated circuit manufacturing process by Intel. Due to its highly controlled deposition parameters (thickness, components and structure), excellent thickness uniformity and consistency, ALD was widely used in the fields of microelectronics.

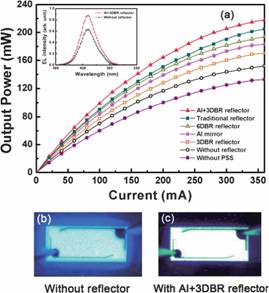

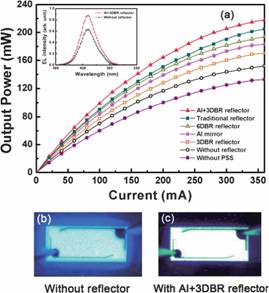

Aiming at the shortage of e-beam evaporation such as non-uniform thickness of DBR and low productive efficiency, Microwave Devices and Integrated Circuits Department of IMECAS proposed high performance DBR (distributed bragg reflection) structure to improve the light extraction efficiency of semiconductor light-emitting devices. The researchers developed high luminous efficiency GaN-based LED using ALD-Al2O3/TiO2 DBR by studying the material, structure, deposition method and optical measurement of ALD-DBR. The output power of GaN-based LED was increased by 43%.

The research results have been published in APEX (Enhanced Performance of GaN-Based Light-Emitting Diodes by Using Al Mirror and Atomic Layer Deposition-TiO2/Al2O3Distributed Bragg Reflector Backside Reflector with Patterned Sapphire Substrate, Applied Physics Express 6(2013) 022101), which is one of the 20 most-downloaded papers that month. The results attracted broad attention in the worldwide, which was reported by Semiconductor Today, LED Professional and LEDs technology. Meanwhile, the research team is cooperating with BENEQ (ALD manufacturer) for further development.

Fig. 1. Schematic diagram of the LED with the backside reflector composed of TiO2/Al2O3 DBR and Al mirror grown on the backside of a PSS. The insets show the SEM images of the fabricated DBR and PSS. (Image by IMECAS)

Fig. 2. (a) LOP of the fabricated LEDs as a function of injection current. The inset shows the EL spectra of the fabricated LEDs. (b) and (c) are photographs of the LED chips with and without a backside reflector in the operating state, respectively. (Image by IMECAS)

|