Japan-based oil company Showa Shell said it will convert a now-empty Hitachi plasma display factory to CIS module production, investing ~$1.1B to establish its third solar production facility. The converted plant is expected to begin operations in 2H 2011, with 900 MW worth of capacity, making it one of the largest PV fabs worldwide.

David Lammers, News Editor -- PV Society, 9/8/2009

Showa Shell Sekiyu KK (Tokyo) said it will set up a 900 MW capacity solar module plant, investing ~$1.1B to convert a dormant plasma display factory now owned by Hitachi Plasma Display Ltd. (Tokyo).

The Japanese oil refiner's subsidiary, Showa Shell Solar KK, already operates two thin-film manufacturing plants, based on copper-indium-selenium (CIS) technology. Those two plants have ~80 MW of capacity, but the third CIS facility will dwarf those, becoming one of the largest solar manufacturing sites worldwide when it goes into operation in the second half of 2011. All three sites are on the southern main island of Kyushu, in Miyazaki Prefecture, and together will be able to produce 1 GW worth of modules annually. The company first indicated its plans for such a large production facility in mid-2008. The facility is expected to employ ~800 people, with ~400 possibly transferring from Hitachi Display to Showa Shell Solar.

The company seeks to have a 10% share of the world PV market by 2014, deriving ¥50 billion (~$500M) in pretax profits from its PV business, according to Jun Arai, president of Showa Shell. "We will consider the construction of a fourth and fifth plant while monitoring the development of the global market," said Shigeya Kato, Showa Shell chairman. Showa Shell is the Japanese subsidiary of Royal Dutch Shell, and counts Saudi Arabia-based Aramco Oil as its second-largest investor.

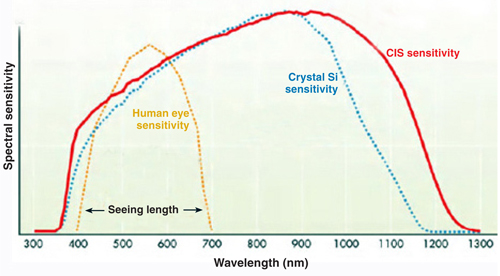

Showa Shell is working to boost the conversion efficiency of the CIS cells to 13-15%, roughly comparable to silicon-based cells. According to the company's website, CIS modules can be produced "at lower cost with less raw materials required and approximately half the manufacturing process steps" compared with crystalline silicon (c-Si) modules.

"In addition, CIS modules are environmentally friendly products with a drastically reduced energy payback time (period required for the recovery of energy consumed during manufacturing through power generation), and Showa Shell's CIS modules do not contain toxic materials such as lead and cadmium," the company says.

Hitachi Ltd., which employs 400,000 worldwide with revenues of ~$102B from its array of businesses, issued a press release saying it "intends to build a cordial business relationship with Showa Shell Solar and look at the possibility of cooperation between both companies."