GlobalFoundries said it has formally completed the integration with Singapore's Chartered Semiconductor. The enlarged foundry will offer manufacturing in all three regions once the Malta, N.Y., fab is finished in 2012. "We are sending out a strong message that we will be an integrated company across the globe, with regionalized manufacturing," said Tom Sonderman, vice president.

David Lammers, News Editor -- Semiconductor International, 1/13/2010

GlobalFoundries Inc. officially brought Chartered Semiconductor Manufacturing Ltd. into its fold today, moving the GlobalFoundries operations headquarters to Milpitas, Calif., and beginning a head-to-head foundry competition with Taiwan Semiconductor Manufacturing Co. Ltd. (TSMC, Hsinchu, Taiwan). The launch of the expanded GlobalFoundries comes slightly less than a year after the new foundry's February 2009 spinout from Advanced Micro Devices Inc. (AMD, Sunnyvale, Calif.) with the financial backing of Abu Dhabi's Advanced Technology Investment Corp. (ATIC), which then bought Chartered late last year.

More than 100 GlobalFoundries staffers have moved from Sunnyvale into the former Chartered building in Milpitas. The company held staff celebrations today with ~10,000 GlobalFoundries workers participating, starting in Singapore, then in Dresden, Germany, and then at U.S. locations in Milpitas; Austin, Texas; and Malta, N.Y., led by CEO Doug Grose, who was scheduled to describe the new foundry's offerings on CNBC television today, with former Chartered CEO Chia Songhwee, now the COO of GlobalFoundries.

|

|

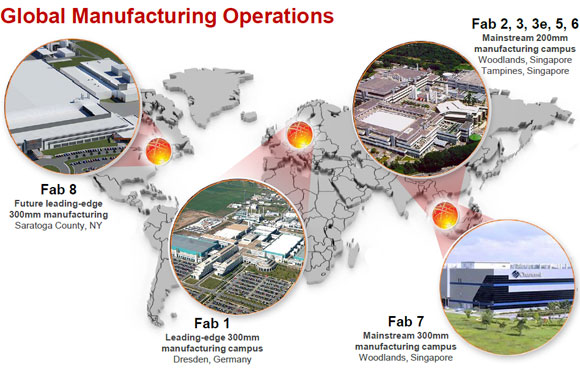

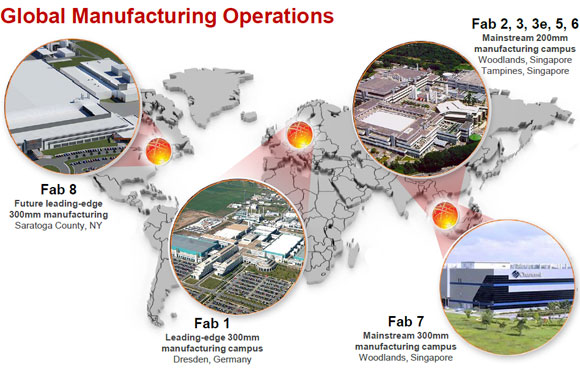

GlobalFoundries will offer manufacturing in the three major regions of the world. |

The 300 mm fab in upstate New York, expected to begin production in 2012, is now referred to as Fab 8, and the two fab modules in eastern Germany are now called Fab 1. Those 300 mm fabs bookend the 300 mm fab in Singapore, Fab 7, along with another five 200 mm fabs in Singapore. By 2014, GlobalFoundries said it expects to have annual capacity for 1.6 million 300 mm wafers, and 2.2 million 200 mm wafers, for a total of 5.8 million 200 mm equivalents.

Thomas Sonderman, vice president of manufacturing systems and technology, said the GlobalFoundries alliance with Arm Ltd. (Cambridge, UK) includes a major effort to establish the Cortex A9 processor core at 28 nm, offering customers a low-power core for system-on-a-chip (SoC) solutions aimed at mobile systems. The Cortex effort sets up a competition with Intel Corp.'s Atom processor core, he noted.

"We have all the elements to be a true competitor at the leading edge, including the service functions," Sonderman said. The acquisition of Chartered adds ~150 customers, including many large companies that had used Chartered for chips not quite at the bleeding edge. Those customers, Sonderman said, will now transfer more of their leading-edge production responsibility to GlobalFoundries.

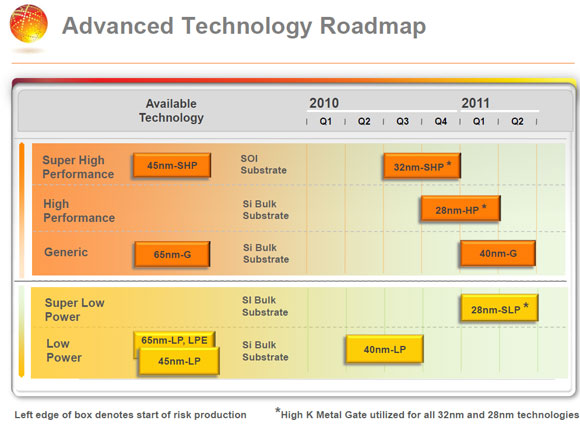

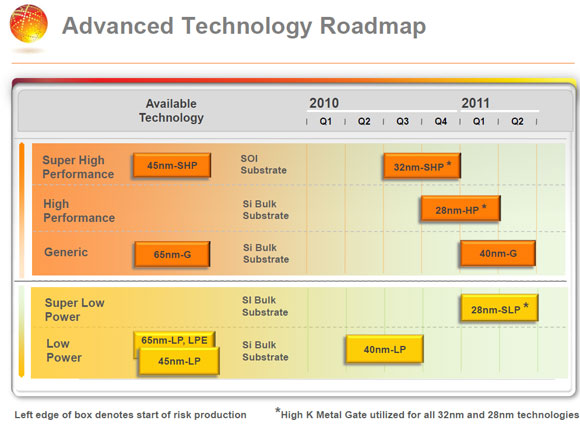

Fab 8 in Malta will be targeted at 28 and 22 nm when it is finished. Plans call for the Dresden complex to concentrate on 45 and 32 nm production, while preparing for 28 nm bulk production beginning next year. The Dresden fab will handle a much wider variety of customers than in the past, running multiple reticle sets of both SOI and bulk designs.

|

|

GlobalFoundries will offer a low-power 28 nm process beginning next year. |

Fab 7 in Singapore will handle 65 nm production, initially. "Chartered, through lack of investment capability, has struggled to keep at the leading edge," Sonderman said. "By being part of GlobalFoundries it will be able to offer more complete technologies."

The Dresden complex is being expanded to 60,000 wpm; Singapore is being equipped to handle 50,000 wpm; and the New York fab will be able to handle 40,000 wpm. Jim Doran, a former AMD executive, is in charge of 300 mm manufacturing technology, and Rajeev Kumar will be the lead technology manager for the 200 mm operations.

Sonderman — who earlier directed the Automated Precision Manufacturing (APM) operation within AMD — said the APM technology will be implemented within the Chartered fabs this year. "This is more of a ‘copy smart' model than a ‘copy exact' approach. We are sending out a strong message that we will be an integrated company across the globe, with regionalized manufacturing," Sonderman said.

"By using APM, we can quickly tune our processes. STMicro might want a slightly different window than other big customers, and we can do that with APM. Working with AMD all those years, we know what it takes to work with an IDM," he said.

The new foundry's timing is good. During the downturn, "many IDMs shifted to a fab-lite model," Sonderman said. Others are engaging with GlobalFoundries as a balance to TSMC, which has dominated leading-edge foundry production over the past two decades.

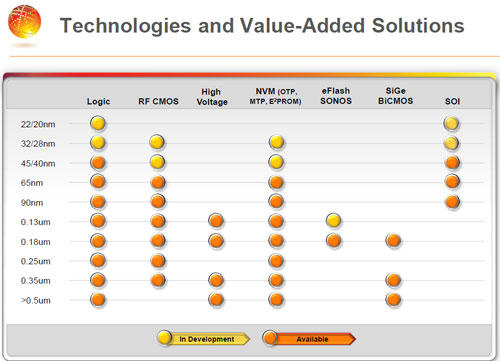

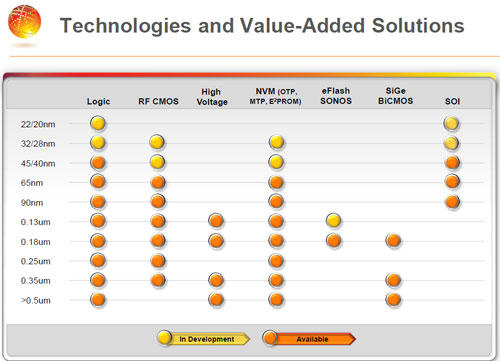

GlobalFoundries also is filling out its technology offerings, including embedded flash, SiGe BiCMOS, perhaps an embedded SOI DRAM offering, and RF CMOS modules. "A year from now we will have a full suite of technologies," Sonderman said.

|

|

A full suite of technologies is planned, depending in part on customer needs. |