|

|

| Promising CNT Coating Suffers From Unexpected Wrinkles |

|

Text Size: A A A |

|

NIST and North Dakota State University researchers have discovered that a promising nanotube coating has unexpected wrinkles, and is seeking ways to keep the nanotube network from changing too much in response to stress. The coating may improve solar cells, providing a cheap, flexible, transparent coating that conducts electricity, as well as semiconductor devices.

Alexander E. Braun, Senior Editor -- Semiconductor International, 4/8/2010

A closer look at a promising nanotube coating that might someday improve solar cells as well as other semiconductor devices has revealed unexpected wrinkles. Research conducted at the National Institute of Standards and Technology (NIST, Bethesda, Md.) and North Dakota State University (NDSU, Fargo, N.D.) is expected to help scientists iron out a solution.

Led by Erik Hobbie, a physical scientist at NIST's polymer division and director of the Materials and Nanotechnology program at NDSU, the group discovered that coatings made of single-walled carbon nanotubes (SWCNTs) are not as deformable as had been expected, which indicates that they are not an easy answer to some of the problems presented by other materials. Although nanotube films possess many desirable properties, the team's findings reveal issues that need to be addressed before realizing the full potential of these coatings.

Hobbie, who has worked on the flow properties of CNT fluids and suspensions since 2002, said polymer composites address a promising market. "The idea is to put CNTs in some sort of plastic and make a network," he said. "That way you get a plastic that conducts electricity, but at nanoparticle concentrations that are quite low compared to more conventional conductive fillers, such as carbon black."

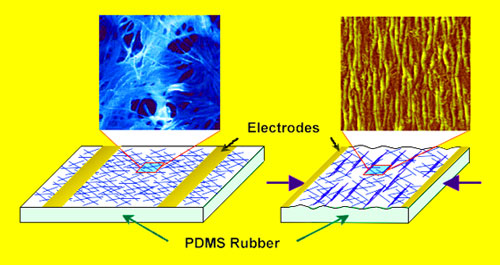

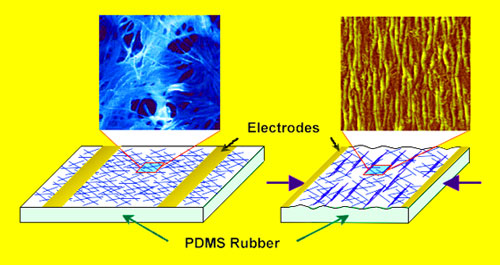

The AFM image on the right shows wrinkling in a single-walled carbon nanotube membrane; the left inset shows an optical reflection micrograph of the membrane without any strain. Each image is 40 µm wide. (Source: NIST)

The irony of these nanotube coatings is that they can change when they bend. "Under modest strains, these films can develop irreversible changes in nanotube arrangement that reduce their conductivity," he said. "Our work is the first to suggest this, and it opens up new approaches to engineering the films to minimize these effects."

High on the wish list of the solar power industry is a cheap, flexible, transparent coating that conducts electricity. If this combination of properties could be realized in a single material, solar cells might become less expensive, and manufacturers might be able to put them in unusual places — such as clothing. Transparent conductive coatings can be made of indium-tin oxide (ITO), but their rigidity and high cost make them less practical for widespread use. CNT coatings are a possible replacement for ITO, and the NIST/NDSU work sets up the scientific framework that would be used by an engineer to consider the problem and select the parameters to optimize the performance of these nanotube coatings. In this case, performance refers to both the electrical conductivity and in some sense the mechanical properties. CNTs show great promise, but with relatively little commercial success so far.

Nevertheless, CNTs are very attractive. They are inexpensive, easy to produce, and can be formed en masse into transparent conductive coatings whose web-like inner structure makes them not only strong but deformable — like paper or fabric. However, the team's research revealed that some kinds of stretching cause microscopic "wrinkles" in the coating that disrupt the nanotubes' random arrangement, which is what makes the coating conduct electricity.

Processing techniques like injection molding coating, or flow processing, can have a major effect on these networks. "When you apply any kind of stress, like pushing them through a pipe or something similar, they will flow but the process ‘wrinkles' them, breaking up the network and compromising conductivity. Once you get the material into your application you have to wait for the network to reform," Hobbie said. "You want the nanotubes to stay randomly arranged. But when a nanotube coating wrinkles, it can lose the connected network that gives it conductivity. Instead, the nanotubes bundle irreversibly into ropelike formations."

The research work conducted thus far at NIST and NDSU indicates that the notion of flexibility must be further specified, because certain ways in which these membranes deform affect performance. One approach is to modify chemically the nanotubes to make them stick together. "That works," Hobbie said, "but we're trying to avoid it, because that kind of active chemical modification can sometimes have detrimental effects on the nanotubes' intrinsic properties. We're trying to come up with more passive approaches." This goal should open new research areas, as well as point to new approaches to engineering these materials.

The study suggests ways to address the problem. The films might be kept thin enough to avoid wrinkling in the first place, or designers could engineer a second interpenetrating polymer network that supports the nanotube network to keep it from changing too much in response to stress. At present, the NIST/NDSU group is separating the nanotubes into metallics and semiconducting, and carrying out the same experiment to determine whether one particular electronic type will better withstand these types of compressive and tensile strains. The work is proceeding well, according to Hobbie. The team has some preliminary data, but he said it is too soon to say which type will be more promising.

"This is not a showstopper," Hobbie said, "but an opportunity to do some more clever engineering."

|

|