|

In December 2010, the construction of statistical process control (SPC) system project of Microwave Device and Integrated Circuit Department (Department no. 4) was preliminarily accomplished with a success after their elaborate and careful planning, which marks that the product process quality management of Department no. 4 will step onto a new stage.

In order to ensure the quality of project products during the manufacturing stage, the processing procedure during the production needs to be effectively monitored, to prevent and detect timely any particular reasons for variations, and to take measures in order to keep the process under the state of statistical control; in February 2010, the Department set up a SPC project implementation group under the full support of the department management, with Wei Ke as the group head, and the group members include researchers on processing platform, test platform, development platform, and those from various project groups. The director of the Department, research fellow Liu Xin-yu personally takes charge of supervising the implementation and management of the SPC project.

After 10 months of project implementation, and with the joint assistance by all the members of the whole GaN subject group, test platform and processing platform, it has now substantially completed the establishment of the SPC system, and the primary monitoring of the processing platform equipment and processing flow has been achieved, which has laid the foundation for the standardized management of processing platform equipment and processing flow, and would ensure the technological level and capability of the production technology platform.

Regarding the establishment of the SPC system, it has mainly completed the following four parts of work:

1. In order to ensure the effective operation of the SPC system, an environment suitable for implementing the SPC has been established.

In order to ensure the effective operation of the SPC system, a detailed program for promoting the construction of the SPC system and a practical and feasible implementation plan were prepared, with three sessions of the SPC system trainings being carried out, and implemented a review mechanism by weekly routine meeting was practiced during the work to form a closed-loop system for solving problems. In order to ensure the continued improvement of the process capability, a set of the SPC system documents are compiled, which are subject to regular review and verification by the quality division.

2. A setting and controlling scheme for the processing control points in SPC

By analysizing the high-level flow chart of the orignal processing platform and processing links to be introduced, 36 key process nodes have been determined, and aiming at the SPC control points preliminarily set, we have carried out strict monitoring during the whole process of the product development of this project.

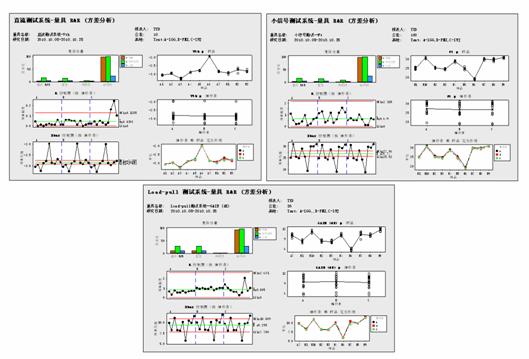

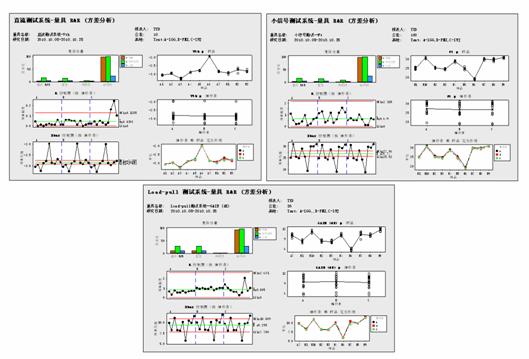

3. The configuration of a suitable measurement system

In order to ensure the stability and relaiability of test data, a systemic measuring system analysis according to a measuresure system anylaysis program and plan, and a SPC test scheme has been conducted. By carrying out the measuring system analysis (MSA), it has provided an ensuring support in configurating a suitable measurement system.

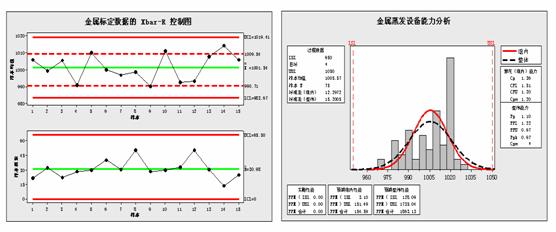

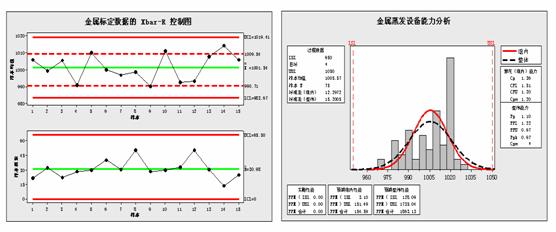

4. Monitoring of the processing flow and processing line equipment

Aiming at the production flow of GaN power devices, some of the key processing control charts have been drawn, and this has accomplished a preliminary monitoring of the processing flow.

For the SPC abnormalities discovered during the monitoring process, they are improved basically by following the closed-loop treatment principle, allowing the production process to recover to the statistic control state.

By constructing the SPC system, the members of the project group have gained a more comprehensive understanding of the SPC, so that they can make better use of the process control and improvement idea and scientific statistic methods to carry out scientific and research activities, to improve work efficiency, make rational distribution of resources, and achieve the value maximization.

Fig. 1 SPC main control content

Fig. 2 Charts of a measurement system analysis example (DC, small signal, Load-pull measurement system)

Fig. 3 Examples of control charts under a controlled state, and charts of process capability analysis

|